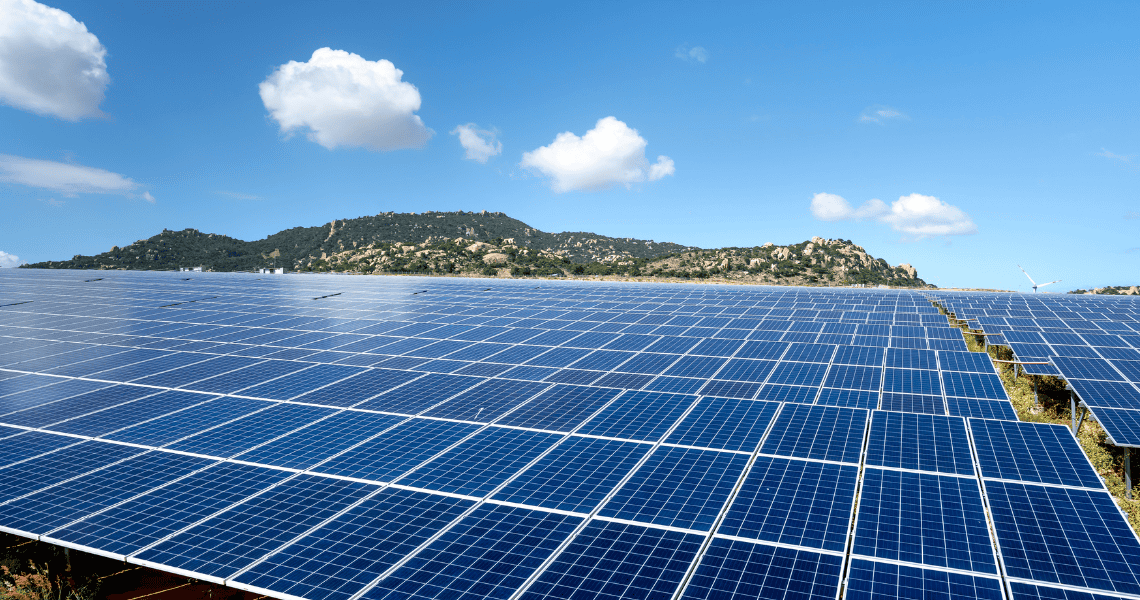

THE IMPORTANCE OF FASTENERS IN SOLAR PANEL INSTALLATION

In the renewable energy industry, particularly in the installation of solar panels, the reliability and durability of every component is crucial. Fasteners play an essential role in ensuring the stability and longevity of the structures that support solar panels. Below, we will see how SNK SYSTEM’s high-strength fasteners contribute to the safety and efficiency of solar installations.

CHALLENGES IN SOLAR PANEL INSTALLATION

Solar installations are exposed to severe environmental conditions, including extreme temperature variations, humidity, wind, and mechanical loads. These factors can negatively affect the integrity of the fasteners if high-quality products are not used. Additionally, the expected lifespan of a solar installation is 20 to 25 years, which means that every component, including the screws, must withstand the test of time without compromising safety.

ADVANTAGES OF SNK SYSTEM FASTENERS

CORROSION PROTECTION:

SNK SYSTEM fasteners are coated with zinc-nickel, using our unique JR2000®+ coating, which offers excellent corrosion resistance (over 3000 hours in SSC) even in C5 environments. This is crucial for solar installations that are often exposed to harsh weather conditions.

HIGH STRENGTH AND DURABILITY:

Grade 8.8, 10.9, and 12.9 screws are designed to withstand high loads and stresses, ensuring that structures remain stable even under strong winds and additional mechanical loads.

FLEXIBILITY AND ADAPTABILITY:

SNK SYSTEM offers standard fasteners as well as custom-made fasteners, allowing customers to obtain products tailored perfectly to the specifications of their solar projects.

ADVANTAGES OF JR2000®+ COATING OVER OTHER COATINGS:

ADVANTAGES OF JR2000®+ COATING COMPARED TO GALVANIZED (HDG)/LAMELLAR COATINGS

SUPERIOR CORROSION PROTECTION

JR2000®+ offers exceptional cathodic protection thanks to its ZnNi composition, providing more effective defense against corrosion than standard galvanized (HDG) coatings, offering significantly higher resistance to white corrosion compared to HDG and lamellar processes.

HIGH TEMPERATURE RESISTANCE

Capable of withstanding temperatures up to 150°C, making it ideal for applications in working environments where galvanized (HDG) coatings might deteriorate in performance.

DURABILITY AND LONGEVITY

Provides greater durability and resistance to tool abrasion compared to galvanized (HDG) and lamellar coatings, ensuring a longer lifespan for protected components.

ENHANCED AESTHETIC APPEARANCE

Provides a silver appearance and high scratch resistance, ensuring a long-lasting and attractive aesthetic compared to galvanized and lamellar coatings.

GREATER VERSATILITY

Suitable for a wide range of industrial applications, including automotive, machinery, aerospace, renewable energy, and more, whereas galvanized (HDG) coatings may have limitations in certain environments.

EASE OF ASSEMBLY

JR2000®+ offers greater ease of assembly than other processes. Galvanized (HDG) coatings can have excess thickness/lumps that prevent proper threading, similar to lamellar coatings.

MORE EFFICIENT APPLICATION PROCESS

Ensures uniform and durable coverage through an alkaline electrolytic process, resulting in more consistent and reliable protection compared to galvanized (HDG) and lamellar coatings. Unlike a paint layer in lamellar coatings, the zinc-nickel coverage fuses with the base material, allowing for a better and safer tightening torque.

SPECIFIC APPLICATIONS IN SOLAR ENERGY

Structure Mounts: Solar panel mounting systems require secure fastening to support the weight and wind force. SNK SYSTEM screws, with their high strength and anti-corrosive coating, ensure that the structures remain firm and stable throughout their useful life.

Panel Connections: Securing the panels to the support structures is critical. Any failure at these points can compromise the efficiency of the solar system. By using high-quality screws, the connections remain secure and efficient, preventing energy loss and potential damage.

INNOVATION AND DEVELOPMENT

SNK SYSTEM is dedicated to continuous innovation to improve its products and adapt to the needs of the renewable energy sector. Our R&D department is constantly working on developing new coatings and materials to offer the best protection and performance.

SPECIALIZED TECHNICAL ADVICE

High-strength fasteners are an essential component in solar panel installations. SNK SYSTEM products, with their excellent corrosion resistance and high durability, provide a reliable and long-lasting solution for the renewable energy sector. By choosing quality screws, companies can ensure the efficiency and safety of their solar installations, guaranteeing an optimal return on investment and significant savings by greatly reducing maintenance costs.